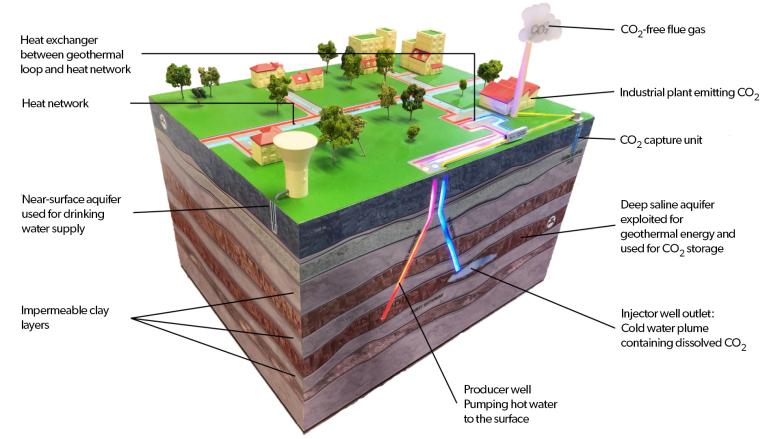

Illustration of a CO2 storage device integrated in a geothermal well, allowing the dissolution of CO2.

© BRGM

Your challenges and needs

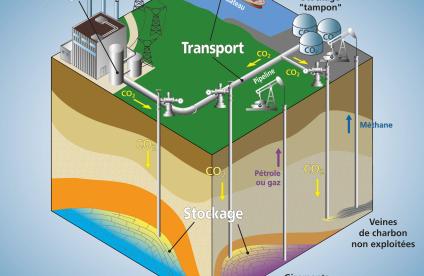

In the context of the fight against climate change, reducing industrial greenhouse gas (GHG) emissions is a major challenge. Geological carbon capture and storage (CCS) appears to be an essential solution for achieving the objectives of carbon neutrality.

The classic approach to geological storage of CO2 in dense gaseous form (supercritical), adapted to industrial plants that emit large volumes, allows several million tonnes of CO2 to be stored per year but remains a complex process in terms of technical and economic feasibility (choice of reservoir, leak-tightness, safety, durability of storage, transport of the CO2 to the injection site, etc.) and is not necessarily suitable for facilities that emit only a small volume.

This is why BRGM has developed an innovative technology called CO2-DISSOLVED, which combines CO2 capture and heat production and is particularly relevant on a regional scale. In France, 12% of the country’s industrial emissions could be avoided with this alternative storage technology. More than 400 industrial sites could be compatible!

Our added value

BRGM has been doing research on the geological storage ofCO2, particularly in deep saline aquifers, for almost 30 years. Since 2012, it has acquired solid experience in studying the technical-economic feasibility of a CCS solution associated with geothermal energy recovery (CO2-DISSOLVED process) which:

- integrates the system into an existing industrial site, for a double environmental benefit, thanks to the reduction of CO2 emissions linked to the industrial activity being coupled with the production of a renewable energy that is largely decarbonised;

- meets local heat needs of the industrial emitter or of its immediate neighbourhood by integrating the heat produced directly into the production chain or by supplying a district heat network;

- meets the needs of small industrial CO2 emitters (less than 150,000 tonnes of CO2 /year), scattered around the country and for which “classic” CCS is not suitable.

This work is based in particular on:

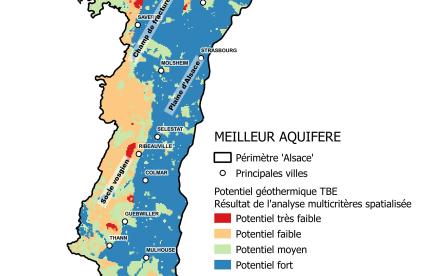

- identifying and characterising a continuous and suitable aquifer: accessibility (between 1,000 and 2,000 m in depth), permeability, water flow rate, temperature (between 50°C and 80°C), nature of the rocks;

- the numerical simulation of injection and storage scenarios to assess the impact of dissolved CO2 on the geothermal reservoir and the environment according to the operational parameters of the planned installation;

- the possibility of integrating an innovative aqueous CO2 capture solution to maximise the efficiency of CO2 recovery contained in the flue gas and its re-injection into the geothermal doublet;

- the establishment of a methodology for risk assessment and monitoring of injection operations.

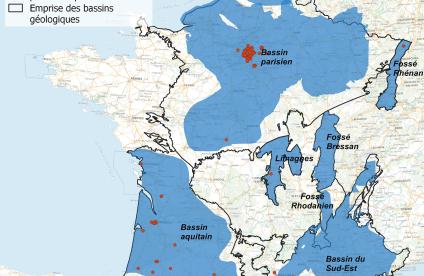

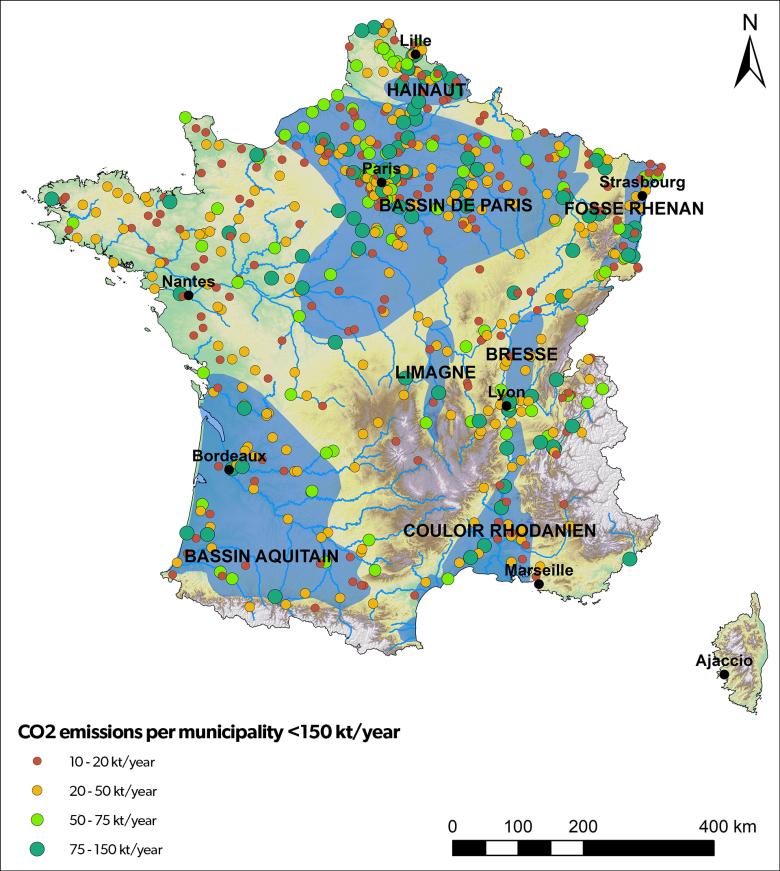

Location of sites potentially compatible with CO2-DISSOLVED technology in France: (437 sites in all, according to 2017 data)

© BRGM

Technical and digital facilities

- COFRAC laboratories for characterisation and analysis of water, rocks and minerals;

- GENIE digital geochemistry platform;

- TER'GEOPHY ground geophysics platform;

- Software for modelling water-rock interactions and migration of dissolved CO2 in the reservoir.

A few references

- Successive research projects (2013-2020), including two with the Géodénergies scientific interest group;

- Preliminary studies of potential or pre-feasibility applied to various industrial sectors (household waste incineration, sugar factories, cement plants, glass production, thermal power plants);

- Opportunity study for the Centre-Val de Loire region;

- Preparation of the first dissolved CO2 injection tests in a geothermal doublet in Ile-de-France.

CO2 Dissolved: carbon dioxide storage and capture

Transcription

CO2-Dissolved is an innovative CO2 capture and storage concept developed by BRGM and its partners since 2012. Particularly well adapted to industries with low CO2 emissions, CO2-Dissolved offers a solution to eliminate or significantly reduce their carbon footprint.

The technology consists in storing CO2 fully dissolved in the water of an aquifer deep down in the subsurface. This water is far too salty to be used as drinking water, and it has the advantage of being naturally hot with temperatures between 40 and 90° C.

The hot water is first pumped up through a well from the aquifer to the surface in order to recover the energy, which can be used for example to supply a heating network for homes. Once the calories have been removed, the cooled water is then used to dissolve the CO2 previously captured from the factory fumes. The cold water and dissolved CO2 are then reinjected into the same aquifer via a second well.

This pumping / reinjection cycle using a set of two wells (called a doublet) operates continuously, as in any classic deep geothermal installation, a technique widely used in the Ile-de-France Region in the Paris Basin. The difference here, is the addition of CO2 in dissolved form in the reinjected water, with a maximum concentration of around 50 kg of CO2 per cubic meter of water.

Calculations show that it would be possible to store in this manner up to 80 to 150,000 tons of CO2 per year, per site. In France, more than 400 industrial sites emitting low quantities of CO2 have been identified that also have underground geothermal resources. This combination enables the potential implementation of CO2-Dissolved. Should CO2-Dissolved be deployed at all compatible sites, this would remove the equivalent of the annual CO2 emissions of 12 million cars.

CO2-Dissolved therefore offers a win-win environmental and economic benefit by reducing industrial CO2 emissions, while producing clean and renewable energy.

This technology brings an innovative solution to small industrial emitters scattered across the territory, allowing them to reduce their carbon footprint and thus contributing to the major challenge of climate-change mitigation.

To find out more

References

Solutions