Your issues and needs

Mineral raw materials (building materials, agricultural fertilisers, base metals and technology metals for transport, digital technologies or electricity generation, etc.) are needed directly or indirectly for all human activities. Whether they come from underground mining or recycling, these mineral materials have environmental impacts throughout their lifecycle, from water and energy consumption, discharges into water, air and soil, and land use.

Faced with the environmental and social issues of our time, society has growing expectations of companies and organisations. At a time when the global economy is multiplying the number of players involved in product and service value chains, ensuring "sustainable and responsible procurement" requires a detailed knowledge of processes and sectors, as well as of their effects on the environment.

Our added value

BRGM researchers analysed the flows of mineral materials in the economy and their impact on the environment, as part of R&D studies focusing on:

- The environmental performance of ecotechnologies for metal production (primary or secondary);

- The mineral resources economy: quantification and criticality of the raw materials needed for developing new industry sectors (energy transition, construction, electromobility, etc.), risk assessment;

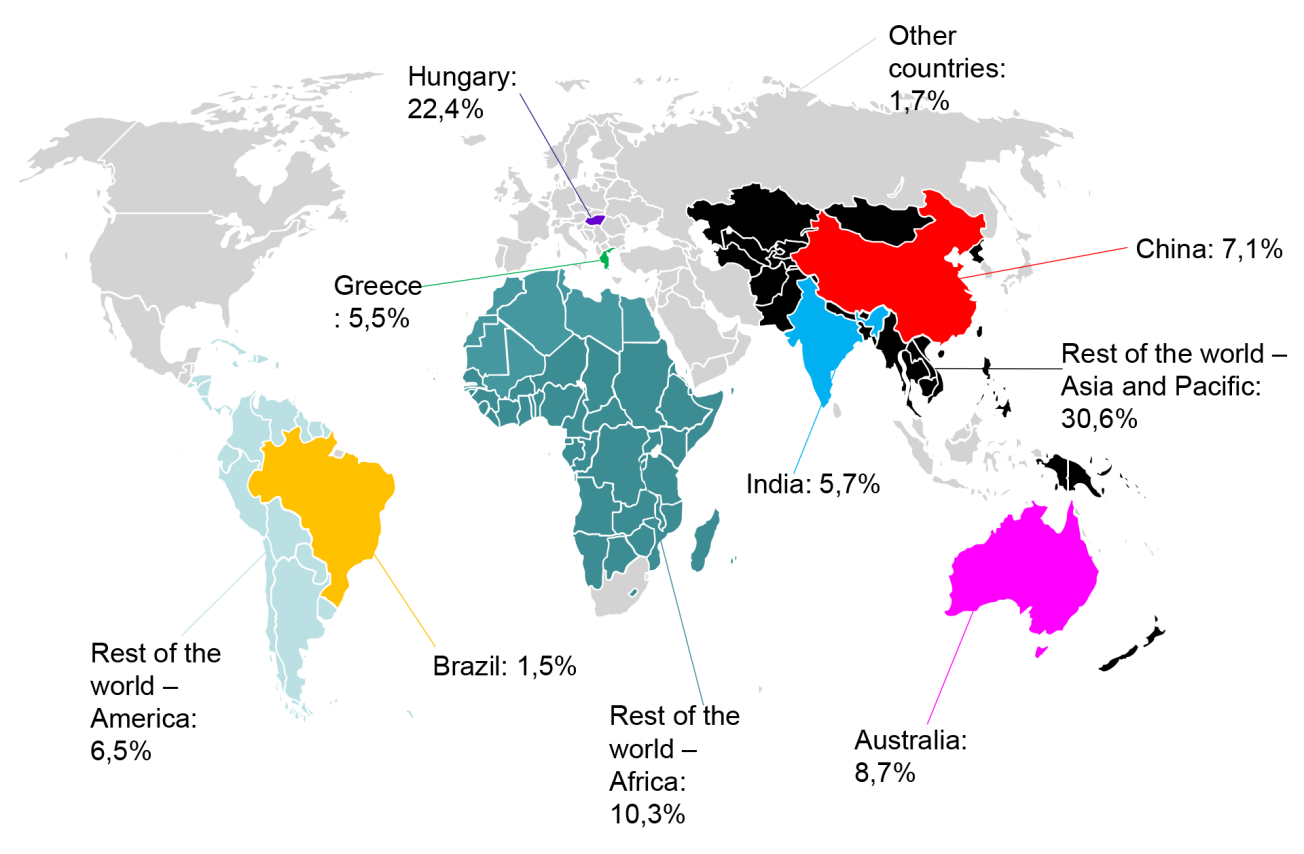

- The mapping of material flows between countries and between industry sectors, and their consequences on the environment (carbon, water, resources, etc.);

- Development of lifecycle analysis methodologies: resource wastage indicators, long-term impacts of mine spoil, etc.

Our proficiency with multi-regional input-output tools (MRIO) and process modelling, coupled with BRGM's expertise in the lifecycle of mineral materials, enabled us to shed light on the environmental issues relating to the procurement of raw materials for an activity. We applied a systemic approach from the process through to the global economy, and were able to trace extraction and emission sites all along the product value chain and identify pollution transfers.

Countries providing the bauxite needed to produce one tonne of frying pans from primary aluminium in France.

© BRGM – Stéphanie Muller

Digital tools

- Matrix calculation on MRIO databases (Exiobase V3 and WIOD)

- Material balance and material flow analysis (MFA)

- Process simulation (USIM PAC)

- Lifecycle assessment (SimaPro - ecoinvent)

- Valuation of environmental externalities

Some references

- Monitoring the carbon footprint of products and services consumed in France and the contribution of metals to this footprint for ADEME;

- Development of circularity indicators applied to material flows and building waste for a metropolis and construction stakeholders;

- Environmental assessment of innovative hydrometallurgical processes for mining operators;

- Comparison of two aluminium procurement scenarios (primary versus recycled) for a cookware manufacturer.

References

Solutions