The former Morandat mineshaft and concrete pithead, to be converted into a Joint Development Zone using geothermal heat from the mine water.

© BRGM

The Gardanne coal mine, which closed in 2003, is currently managed by the DPSM (the BRGM’s Mine Safety and Risk Prevention department). The mine galleries became flooded when pumping was partially shut down after mining ceased, forming a large reservoir of water at temperatures of 20 to 30°C depending on depth (up to 1,000 m).

This potential and as yet unused geothermal resource prompted the city of Gardanne, as part of its renewable energy policy, to commission a characterisation study of the reservoir from the BRGM. Aim: ultimately, to use this potential source of very low energy geothermal heat via heat pumps to cover heating and cooling needs in a planned Joint Development Zone (ZAC) above the Yvon Morandat pit in Gardanne.

Testing different scenarios

In order to characterise the resource, assess its long-term potential to meet needs on the surface and measure the hydraulic, thermal, chemical and bacteriological impacts of extraction, the BRGM undertook several types of studies.

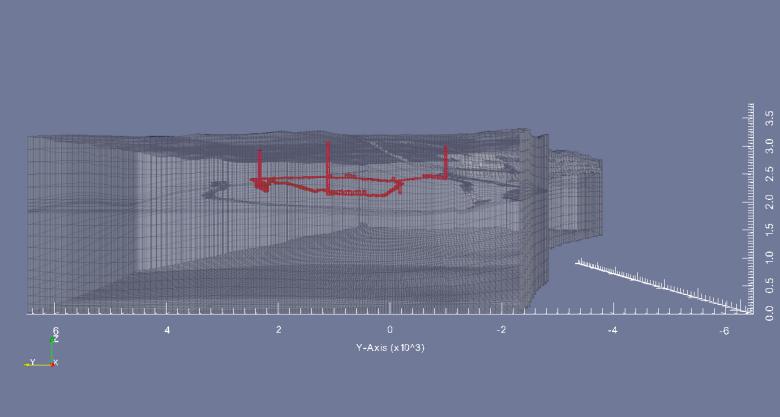

A conceptual model was developed based on a regional geological model and plans of the main galleries linking pits that are still accessible, and run with parameters from different scenarios. The first scenario tested was for the ZAC project as originally designed (heating and cooling needs). Secondly, for the same zone, a data centre was added (substantial cooling needs). The third scenario added heating for an existing residential sector.

The model showed the hydrothermal impacts of the different scenarios and associated technical solutions: cooling needs only, heating and cooling needs, with pumping and reinjection wells or with reversible hot and cold wells. Moreover, because the water becomes highly mineralised due to sulphur oxidation followed by flooding of the mine workings, the characterisation of the resource also included an assessment of the impact of temperature (storage of calories or frigories) and of potential oxygenation effects on the physico-chemical characteristics of the mine water.

Towards the operational phase

These investigations showed the relevance of scenario n° 1, the most favourable, with alternating heat and cold production according to season via a reversible well (the pumping well becomes an injection well, and vice versa), a solution that limits the thermal impacts of extraction on the resource.

This study was able to draw on knowledge acquired during previous work since 2000 with Dutch researchers under the Interreg IIIB project for north-west Europe, and from a pilot site established at Heerlen (Minewater project).

It provided decision-support material and recommendations for the Gardanne municipality on using the mine water for heating and cooling needs. The SEMAG (joint company for Gardanne development) is looking to relaunch the project with further investigations into other solutions (pumping and reinjection in a single well, closed loop geothermal exchanger) and their installation costs, with a view to setting up a pilot in 2016.