Interview of Sandrine Vergne, Technical Development Engineer, Technical Department, Eurovia.

Why did you call on BRGM to work with you on the “positive-energy road” project?

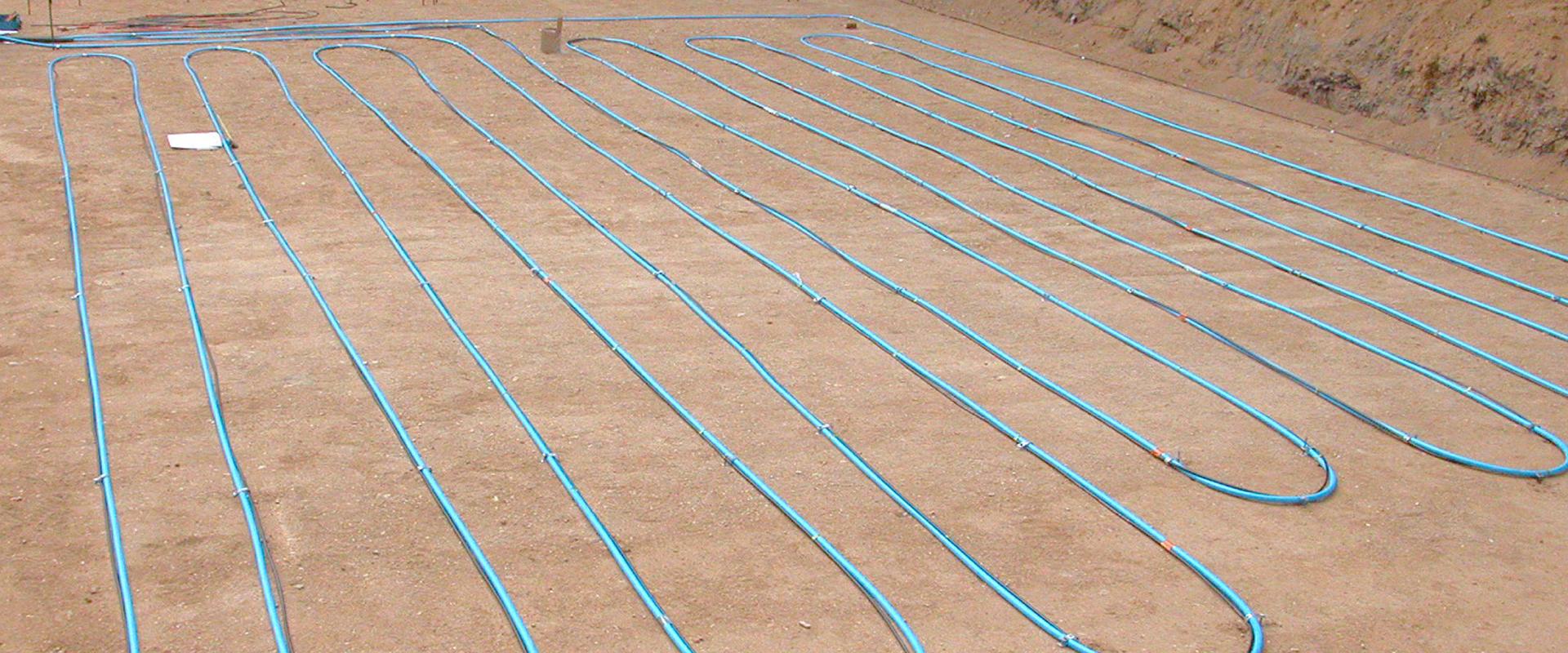

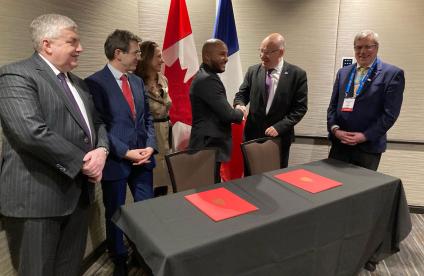

Sandrine Vergne: Two years ago, Eurovia signed a research contract with BRGM to work on the development of technical solutions to create “positive energy roads”. Power Road® uses heat exchangers placed in the road to recover the solar heat absorbed by the road surface so as to heat urban facilities (buildings, shopping centres, swimming pools). Since the efficiency is highest in summer, it was obvious we needed to combine the solution with a system for inter-seasonal underground storage. We worked with institutional partners to validate the concept. BRGM is a leading expert in the field of subsurface studies, so bringing them on board seemed a natural choice.

The R&D work focused on establishing a methodology for choosing the most efficient method of underground heat storage in relation to our technology and use cases.

How did you organise the collaboration?

S. V.: We worked in tandem to assess the technical and economic aspects of using Power Road® with underground heat storage solutions: field of geothermal probes, aquifers and underground reservoirs, depending in particular on the local characteristics of the subsurface (geology, hydrogeology, geothermal potential, etc.).

We first determined the scope of the studies and typical cases of different heating and/or cooling needs in buildings, depending on their surface area and geographical location. We then compared the various sizing options for the solution, linking Power Road® to a storage system using a field of geothermal probes: coverage rate of the heat pump, size of the probe field, Power Road® surface area, etc. The key criterion was to optimise the overall cost (investment and operation) in relation to environmental benefits (reduced CO2). The studies were headed up by a joint committee, with experts from Eurovia’s Technical and Research Department and BRGM’s Geothermal and Energy Storage team.

How would you summarise the results after two years of joint work?

S. V.: The project has just ended. Power Road® responds to a real need in terms of reducing CO2. It draws on commonly-used technologies but is highly innovative in the way it assembles and implements different energy-producing devices. More than 10 systems are already in operation in France, as well as in other countries.

To further develop and optimise the system, we need to have access to specific expertise about the subsurface. In this respect, the work carried out with BRGM was a real success. Moreover, various publications and conferences are planned concerning the project, and we are looking at pursuing the work as well as launching other types of studies.