The system installed in Egletons (Corrèze) aims to stop ice and snow forming on a road using the urban heating network.

© Agence Louise/Photothèque Eurovia

The process of capturing the sun’s heat absorbed by road and car park surfaces was developed by Eurovia, using a closed circuit embedded in the asphalt. Innovative and renewable, Power Road® technology recovers the heat produced, particularly in summer. But how can it be stored for use in winter, particularly for heating public infrastructures such as swimming pools, city and shopping centres or social housing? “A large quantity of heat can be stored in the subsurface for a long time by means of a field of vertical geothermal boreholes directly in an aquifer or in an underground tank” explains Antoine Voirand, energy specialist at BRGM.

Limiting investments

Eurovia entrusted the institution with the task of carrying out a technical and economic feasibility study of these solutions, in particular the field of vertical geothermal boreholes, as the other storage methods were more difficult to implement in this context. “Coupling Power Road® technology and a field of boreholes is more about regenerating the subsurface than about heat storage per se” emphasises Antoine Voirand. The temperature of the hot water produced by Power Road®, which varies between 30 and 40°C depending on the solar flux incident on the road, cannot achieve temperatures suitable for direct heat production in the borehole field. “However, by injecting the heat produced in the summer into the subsurface its temperature can be kept constant from one winter to the next, or even increased and therefore the performance of the energy system can be maintained over time, or even to boost it”, continues Antoine Voirand. “This heat supply, which is still within the framework of small-scale geothermal energy, avoids the need for deep boreholes and hence limits the investment requirement.”

For the purposes of this long-term study, the BRGM team calculated the overall cost of the initial investment required, including installation of the Power Road®, the borehole field and the heat pump required for surface geothermal energy. It also estimated the electricity and gas consumption over a 25-year period on the basis of price scenarios and assessed CO2 emissions, again over 25 years, clearly with an environmental component.

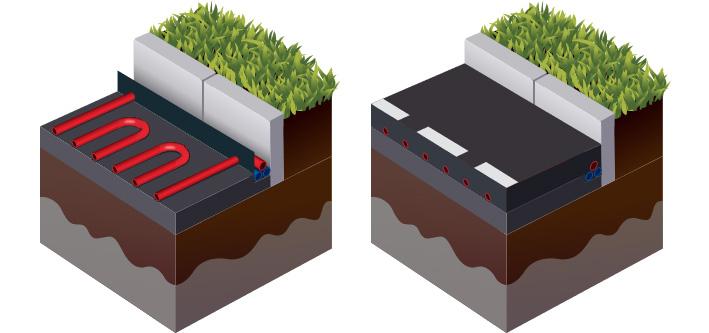

The Power Road® innovation, designed by Eurovia, captures the sun’s heat absorbed by road and car park surfaces. Left: Installation of a heat exchanger in the road surface. Right: Laying a surface layer on top of the heat exchanger.

© Eurovia

Complex parametric studies

In addition, a large number of parameters were taken into account. For each of them, BGRM set out to define the optimum size of Power Road® in terms of surface area and of the borehole field in terms of the total depth and spacing of the boreholes. Other subsoil parameters, in particular thermal conductivity, but also the type of buildings to be heated (multi-family dwellings, single-family houses, hotels, offices, etc.) and the climate were taken into account in order to determine the heating and cooling needs to be considered.

These dynamic calculations were used to evaluate the performance of the Power Road© - geothermal energy combination over 25 years for heating buildings.

Conclusions “As a result of this study, Power Road® can improve the performance of the energy system”, summarises Antoine Voirand. Compared to a conventional geothermal solution, it can simultaneously reduce the total cost of the system by up to 35% and its carbon footprint by up to 20%, depending on the case considered. This was achieved through a substantial reduction in the number of boreholes (up to 70%), although this was partly offset by the installation of a large area of Power Road®.”

The Power Road® solution is based on a solar thermal collector set into the road surface. The solar heat absorbed is recovered by the heat exchanger and can be stored or returned immediately, as in the case of the swimming pool in Feurs (Loire).

© Adrien Cailliau/Photothèque Eurovia

A decision-making aid

The full results of the parametric study are a useful decision-making aid for building heating projects. With this methodological tool, Eurovia can establish the design of the borehole field and the surface area of Power Road® to be installed according to the different parameters considered. This confirms the benefits of the Power Road® solution to supplement surface geothermal energy. “The partnership with Eurovia could continue in the future to provide local information on subsoil characteristics from the point of view of surface geothermal energy or to study the best heating system to design for a particular building,” says Antoine Voirand.

BRGM is a leading expert in the field of subsurface studies, so bringing them on board seemed a natural choice. Power Road® responds to a real need in terms of reducing CO2. It draws on commonly-used technologies but is highly innovative in the way it assembles and implements different energy-producing devices. More than 10 systems are already in operation in France, as well as in other countries.