Launched in 2015, the 3-year ENVIREE project (ENVIronmentally friendly and efficient methods for extraction of Rare Earth Elements from secondary sources) is part of the European ERA-MIN programme, which is developing research on markets for non-energy raw materials.

The EU is aware of Europe's dependence on metals, and has been developing a European policy for non-energy mineral raw materials since 2008. This policy aims to secure long-term access to non-energy mineral raw materials at reasonable cost.

Demonstrating the viability of new sources of rare earths

The rare earths group of minerals comprises 17 metallic trace elements found in most natural environments. Because they have properties that are highly sought-after and essential to the new and advanced technologies industry (including for renewable energy production equipment), rare earths are among the so-called strategic metals. Today, there are risks of supply failures for these metals, either because no viable substitutes or recycling processes exist as yet, or because their production is concentrated in a very few countries, some of which are politically and economically unstable.

ENVIREE is developing methods for extracting rare earths from mine spoil (mainly from the mineralurgy and metallurgy sectors). The mine spoil in question is the residue of treatments to extract base metals, gold or tungsten, and is usually left in heaps close to abandoned or working mines. It has now become possible to consider the recovery of valuable substances from these residues when the volume and content of rare earths makes such operations economically viable.

The project is organised into three topic areas:

- Research: developing new environmentally and economically viable extraction processes for different types of mine spoil;

- Raising awareness: promoting education, training and the communication of research results;

- Economic development: transferring research results to the industrial fabric.

ENVIREE: recovering minerals from mining waste to promote European independence for rare earth supplies

Transcription

The EU project ERA-MIN ENVIREE, coordinated by Chalmers University, and in which the BRGM and the CEA are partners, aims to recover rare earth elements, or REE, from mining waste. Because the waste from mining for other metal contents contain significant quantities of these chemical elements. The pilot is divided into 5 stages. Stage 1, which takes place in a stirred tank, turns waste we have received from Swedish mines into pulp. This mineral pulp is then transferred to a conditioner where it is chemically prepared for the flotation process. Flotation is done in three main stages: grinding, screening and the rewashing of the froth. After these stages, the pulp is transferred to a thickener, and it leaves there to be band-filtered. The concentrates we prepare are sent to the CEA in Marcoule and to Chalmers in Sweden where they undertake the making of REE solutions, liquid-liquid extractions and ionic liquids. The project now continues with the equivalent stages to those carried out on the Swedish mining waste. We've notably received waste from northern Portugal on which we'll reproduce several mineral processing operations such as flotation, gravimetric separation, magnetic separation and electrostatic separation, to concentrate the material so as to supply our colleagues for their dissolving operations.

Improving knowledge on processes applied to minerals and mine spoil

Some fifty sites in Europe and South Africa were assessed with a view to investigating and developing processes for extracting rare earths from mine spoil. Two of these sites were selected for the development of reprocessing methods: a former tungsten mine in Portugal and a Swedish gold mine that produces mine spoil containing monazite, a mineral in which rare earths can be present.

After an initial spoil characterisation phase, the BRGM took responsibility for developing and optimising mineralurgical reprocessing methods capable of concentrating minerals in mine spoil that contain rare earths. The next phases, involving lixiviation of these concentrates, are handled by the Atomic and Alternative Energy Commission at its Marcoule facility.

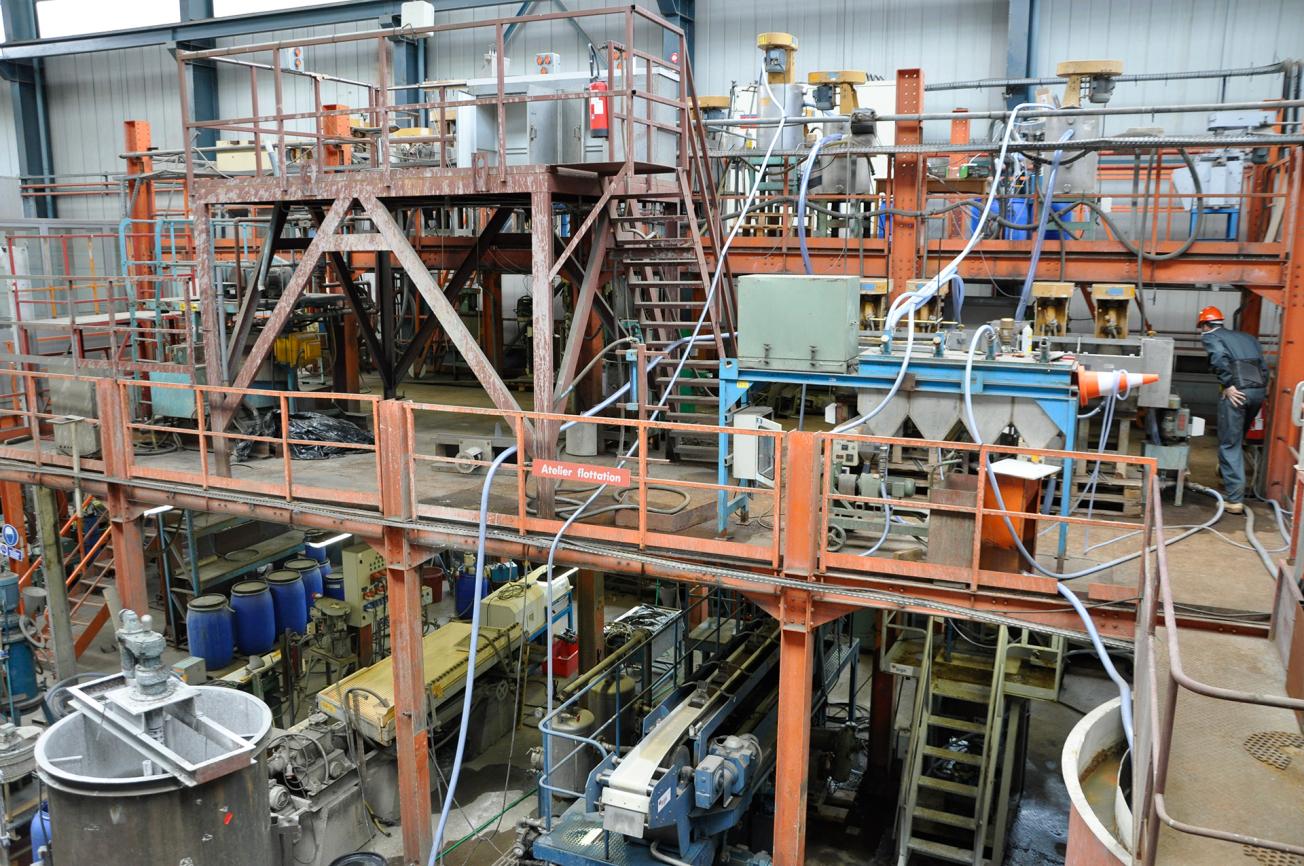

A pilot flotation process developed specifically for the project is used to treat the mine spoil from the Swedish site at the BRGM's experimental facility, an innovation platform for mineral and waste processing. The flotation concentrate obtained is enriched with rare earth-bearing minerals, then undergoes a magnetic separation process that produces a monazite-rich rare earth-bearing concentrate. For the Portuguese mine spoil, the processing method involves a gravimetric concentration phase (Mozley separator) followed by magnetic separation. These processes were developed from laboratory tests that were then scaled up for pilot production at each site at a capacity of one tonne of ore.

A flotation pilot was developed successfully at the BRGM's experimental facility to recycle rare earths contained in mine spoil.

© BRGM

An opportunity for research and industry

The purpose of the ENVIREE project is to demonstrate the economic and environmental feasibility of reprocessing mine spoil to recover the rare earths and other valuable minerals they contain, with a view to diversifying sources of supply for Europe.

Looking beyond the specific issues of the rare earths sector, the project is also aiming to demonstrate the possibility of using the added value of metallic elements contained in mine spoil to facilitate and encourage reprocessing and remediation in abandoned mining sites. The goal in this case is to facilitate reprocessing operations, where economic viability is a frequent obstacle to implementation. When the overall economics of avoiding environmental impacts through reprocessing are incorporated into a project's economic assessment (avoided consumption of raw materials in particular, and remediation of potential pollution from spoil heaps), this contributes to the economic and social interest of projects for mine spoil reprocessing.

Launched in 2015, the 3-year ENVIREE project (ENVIronmentally friendly and efficient methods for extraction of Rare Earth Elements from secondary sources) is part of the European ERA-MIN programme, which is developing research on markets for non-energy raw materials. The EU is well aware of Europe's dependence on metals and has been developing a European policy for non-energy mineral raw materials since 2008. This policy aims to secure long-term access to non-energy mineral raw materials at a reasonable cost.