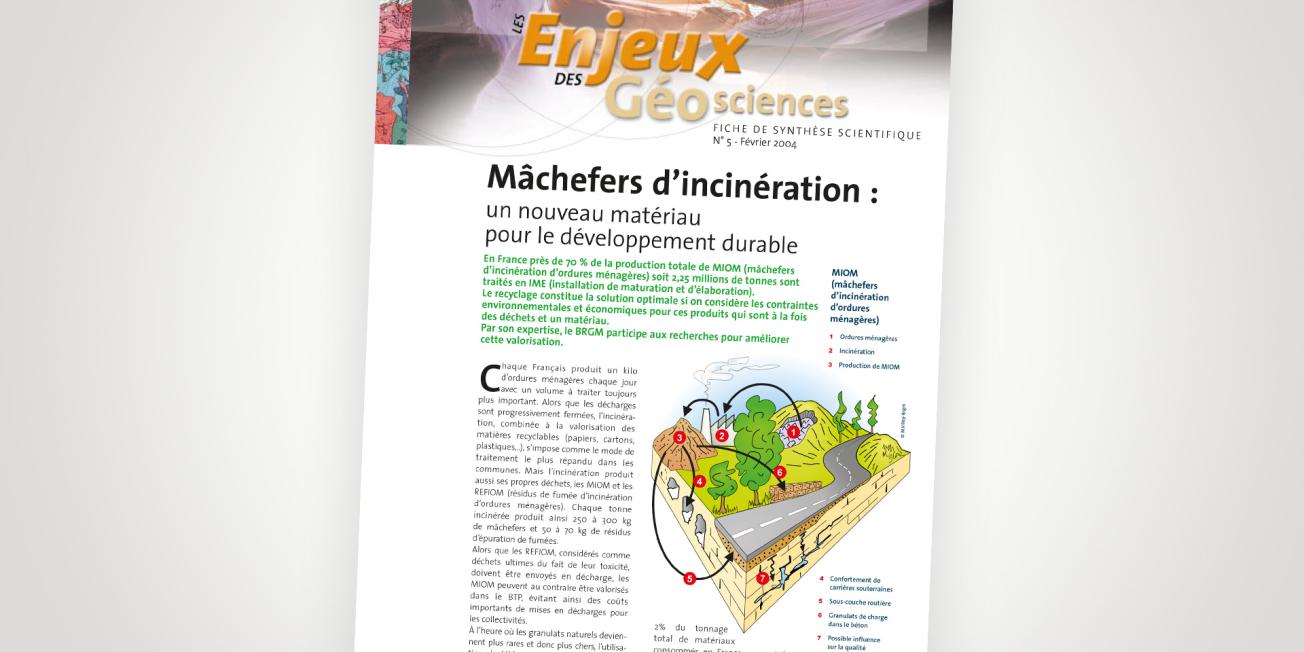

Cover of the data sheet.

© BRGM

A new material for sustainable development: incinerator bottom ash

Every person in France produces one kilogramme of household waste every day, with an ever-increasing volume that needs to be processed. As landfills are gradually being closed, incineration combined with recovery of recyclable materials (paper, cardboard, plastic, etc.) is becoming the most widespread municipal processing procedure.

But incineration also produces its own waste: DWIA (domestic waste incineration ash) and DWIFGR (domestic waste incineration flue gas residues). Each tonne of incinerated waste produces 250 to 300 kg of bottom ash and 50 to 70 kg of flue gas purification residues.

While domestic waste incineration flue gas residues, considered as final waste due to their toxicity, must be sent to landfill sites, domestic waste incineration ash, on the other hand, can be recovered in the construction and public works sector, avoiding major landfill costs for local authorities.

At a time when natural aggregates are becoming scarce and hence more expensive, could the use of domestic waste incineration ash be an economically and environmentally credible alternative?

Could this bottom ash, which accounts for 2% of the total tonnage of materials consumed in France, have an impact on the environment, health, air quality or groundwater?

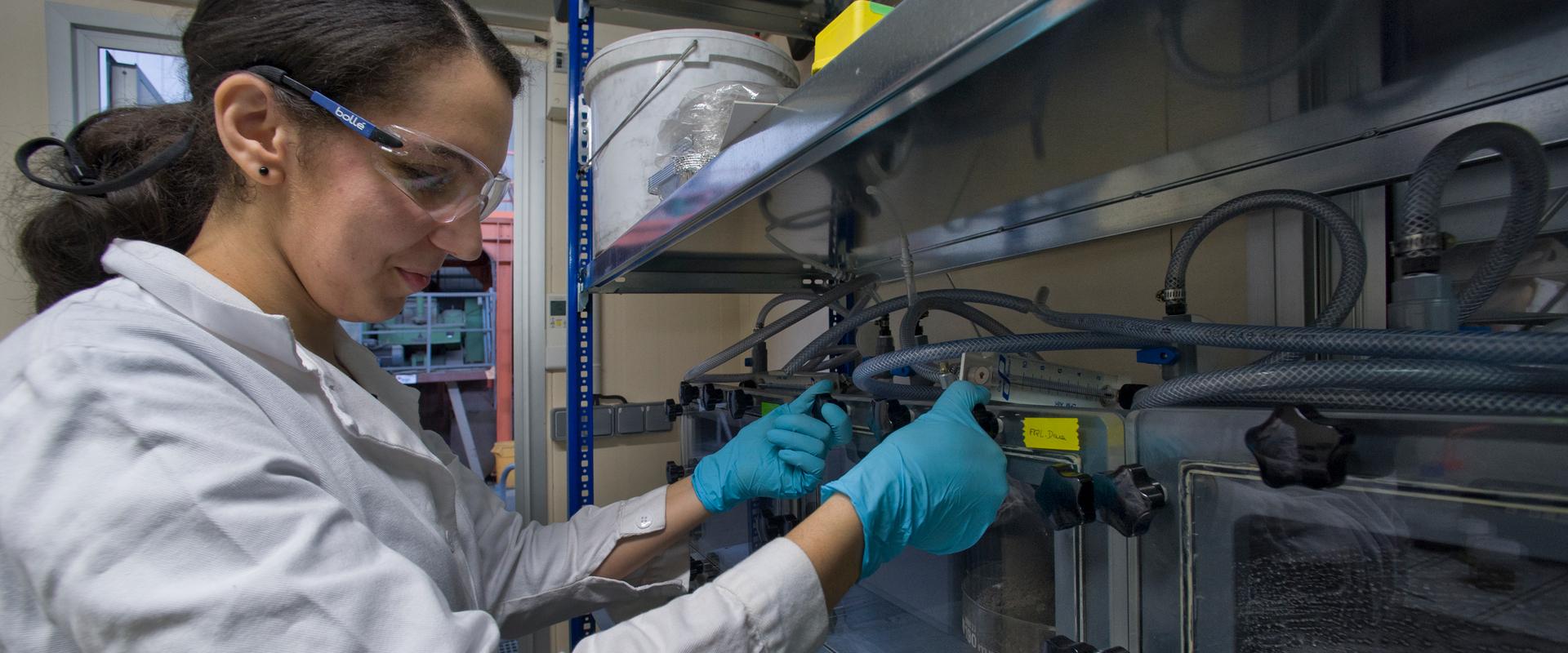

These are some of the questions that BRGM seeks to answer by means of studies to assess the medium- and long-term behaviour of incinerator bottom ash. Recovery of domestic waste incineration ash appears to be a major challenge both for local authorities and for the construction and public works industry.