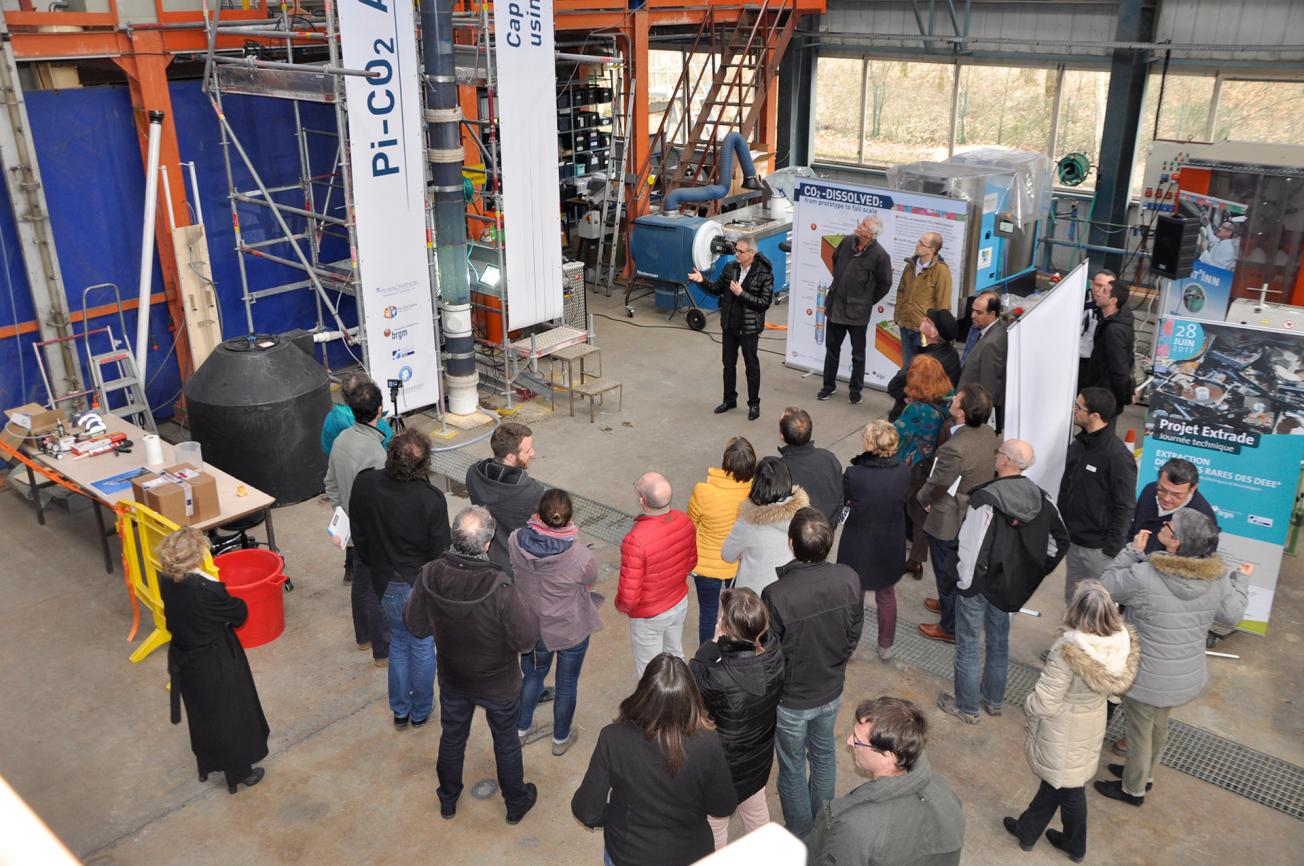

Overview at the inauguration of the Pi-CO2 prototype, on March 20th 2018, at the BRGM experimental pilot hall.

© BRGM - Cyril Boucley

The Pi-CO2 prototype, recently set up in BRGM’s experimental pilot hall in Orléans, is an innovative CO2 capture technology.

Designed in collaboration with two American partners, PI-innovation and The Tech Toybox, the prototype consists of a column of 3 stages, measuring 8.5 m in all, and within which water and gas circulate (co-current within each stage; counter current overall in the column). This design maximises the efficiency of CO2 dissolution and transfer from the gas phase.

Promising environmental and economic prospects

BRGM’s researchers are currently undertaking experiments on the new equipment. Once the dynamics of capture system have been proven, the expected performance indicators will be of particular interest: Pi-CO2 will enable CO2 capture by simple dissolution in water (brine), thus avoiding chemical additives and chemical degradation waste.

The economic simulations carried out are highly promising in terms of cost per ton of captured CO2, which is estimated to be about 50% less than the current leading market technology (amines).

Beneficial effects for the CO2-DISSOLVED project

This capture technology is well suited to the CO2-DISSOLVED concept, which combines storage of industrial CO2 emissions with the production of clean geothermal energy that can be used locally. The CO2-DISSOLVED concept, initiated and led by BRGM for more than 6 years, has been studied and developed through two successive projects respectively co-funded by ANR (French Research Agency) and Geodenergies (a Scientific Interest Group).

In the longer term, by integrating the Pi-CO2 technology into a CO2-DISSOLVED-equipped plant, the industrial sector will have a turnkey solution within their reach. This technology will enable industry to reduce their CO2 emissions through local storage in a deep aquifer hand-in-hand with geothermal energy production.