Mining and processing plant. Wet sand grading process.

© Adobe Stock - nordroden

BILCO is a software allowing you to establish complete and coherent mass balances. It is one of the few software tools that can establish balances automatically.

BILCO uses the principle of material conservation to describe a system. From all the available data (measurements, analyses, estimates) on the flows of material circulating or in stock in a plant or a pilot plant, it allows to accurately analyse the process operation and determine its performances.

BILCO is a decision support tool used for the design, the monitoring, and the optimization of the industrial processes, even the most complex. It is also highly valued by R&D engineers to perform experimental studies.

Its applications are wide:

- estimate at best the yields and performances of a process

- validate measured data for process simulation

- perform feasibility studies

- evaluate the environmental footprint of a process

- estimate the characteristics of a stream (size distribution, chemical composition...)

- establish balances in the field of analytical chemistry or mineralogy

- define sampling and measurement strategies

- carry out quality controls

- etc.

Main characteristics of BILCO mass balance software

- A data reconciliation algorithm adapted to any processes, even the most complex: multiphase flows, recycling, etc.

- A configurable material model: one or several phases (solid, liquid, gas), up to two composition levels (chemical or mineralogical composition, size or density distribution), allowing phase transfers and chemical reaction.

- An easy-to-use graphical interface regardless of your level of expertise.

- Detailed and exportable results in Excel: summaries, comparisons...

BILCO, USIM PAC and ECHANT: a complete suite for analysing transformation processes.

A BILCO module is integrated into the process simulator, USIM PAC. Together with the ECHANT sampling software, it forms a complete suite for analysing transformation processes.

BRGM is the author of the BILCO USIM PAC and ECHANT software. CASPEO is the editor since 2004 and continues to extend the functionalities.

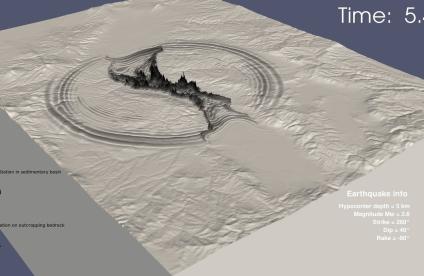

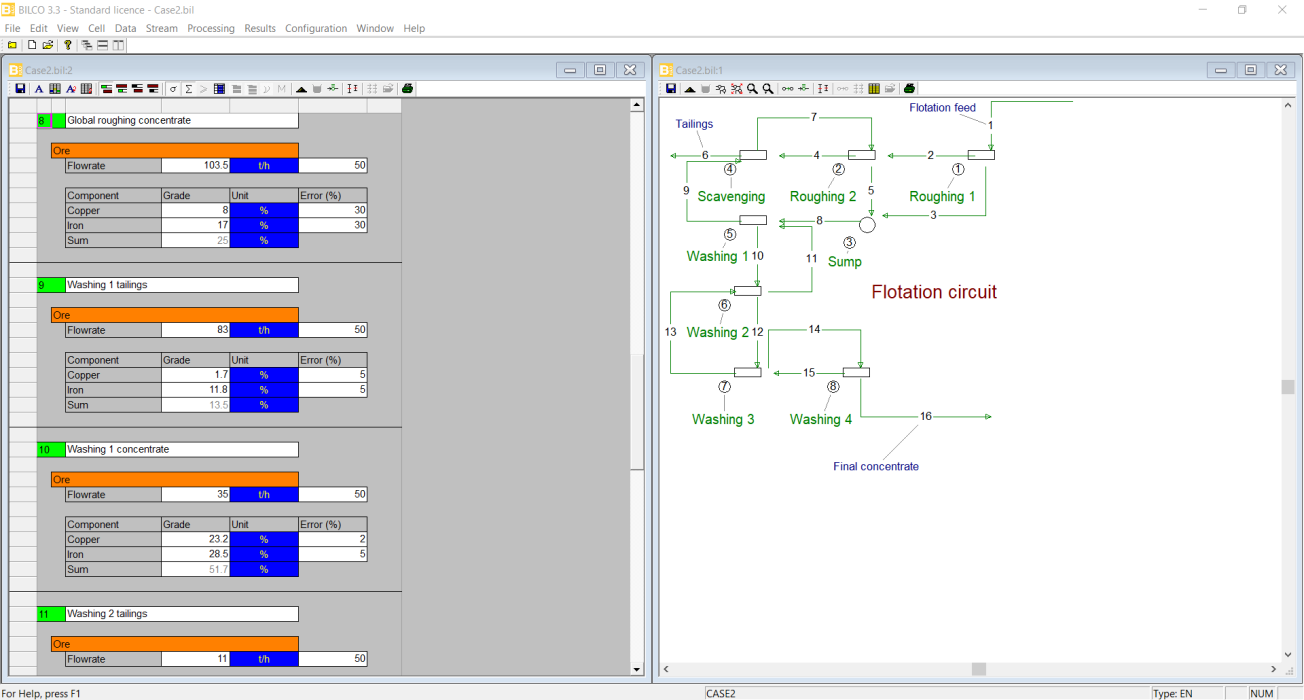

BILCO software interface - Mass balance of a flotation circuit.

© Caspeo

Features

The BILCO software allows to obtain complete material balances verifying mass balance or molar balance equations for all streams. In one shot, it improves the quality of measured data, estimates unmeasured values, and detects gross errors. All these data are visually reachable from the process flowsheet.

BILCO determines the quantity and quality of each process stream. It is one of the few mass balance programs that can calculate all the properties of a stream (flowrates, particle size distribution, particle types, mineral, chemical or molar composition, etc.) in a single calculation.

With BILCO, you get a complete mass balance. You are then ready for the next step: modelling and simulation of your processes.

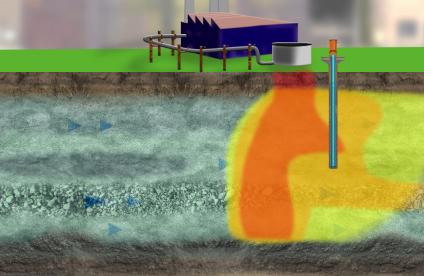

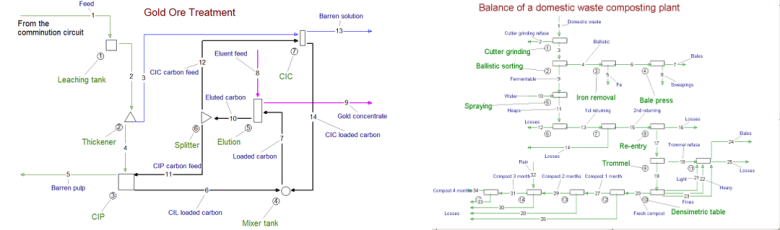

Mass balance of a hydrometallurgical plant for gold (left) and of a waste treatment plant (right) produced with BILCO.

© Caspeo

Applications

BILCO is a data reconciliation software for any industrial process:

- Mineral processing

- Metallurgy

- Food, biomass

- Chemicals, petrochemicals

- Municipal and industrial waste management

- Water flow networks and pollutant balances

- etc.

BILCO can also be used for all types of balancing problems for chemical analysis (fitting up to 100 % and estimating accuracy of analysis), mineralogy (fitting with chemistry), definition of sampling strategies, mixing and blending, etc.

Discover the Bilco software

To find out more

Publications

Mango, D-A., Brochot, S., Saparova, s., Kobzhanov, A. (2020) - Uranium accounting reconciliation. Proceedings of the Uranium Virtual Conference hosted by COM 2020. https://www.metsoc.org/publications/

Brochot, S. (2020) – The material balance: a key step between measurement and process control. Proceedings of SIM 2020 congress, Angers (France) published in French in Mines & Carrières magazine – Hors série numéro 28 – May 2021. Available in English on demand on: https://www.caspeo.net/process-engineering-blog/

González, M., Brochot, S. , Durance, M-V. (2018) - Applying data reconciliation to improve flotation process assessment. Proceedings of Flotation 2018 conference, Lima, Peru.

Spolaore P., D'Hugues P., Durance, M.-V. Morin, D. (2007) - Optimization of the monitoring of a continuous bioleaching process. Récents progrès en génie des procédés - Numéro 96 - 2007 ISBN 2- 910239-70-5, Ed. SFGP, Paris, France.