Plat'Inn: a BRGM technological platform for mineral resources and recycling

Transcription

Mineral resources are omnipresent in our daily life. The demand for them is constantly rising and access to these resources is increasingly complex and energy intensive. On arrival at the BGRM processing facility, the waste and ore undergo numerous treatment stages. Before processing the waste or the ore, it is important to sample a small representative part for mineral analysis and characterization. It allows the production of small batches for treatment experiments. It's possible to combine grinding with a thermal treatment which weakens the matter before its fragmentation. This operation can be carried out with different types of ovens, including a microwave oven. Once the material is ground, the grains of interest are sorted and recovered and the others are left behind. This separation is based on the differences in grain properties. Magnetic, eddy current and electrostatic response and density.

The Plat'Inn platform

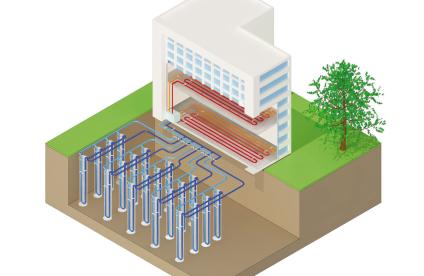

Plat’Inn supports the processing of mineral resources and the recycling of waste that could potentially become a source of raw materials. The platform provides a link between laboratory research and industrial-scale production and has a variable processing capacity from a few dozen kilos to several tonnes.

The platform incorporates different tools and specialised workshops for:

- material fragmentation and sampling

- mineral processing

- thermal treatment

- hydrometallurgy

- separation through wet and dry processes.

The versatility of the platform environment allows innovative solutions to be demonstrated for the advancement of integrated, optimised and sustainable processing concepts.

Discover our virtual tour of the Plat'Inn platform

Applications

Processing of metal ores and industrial minerals

- Development of flexible and mobile technologies for the exploitation of complex polymetallic resources;

- Development of a new type of reactor for the bioleaching of metals from low-grade resources;

- Environmental assessment of innovative hydrometallurgical processes for mining operators.

Characterisation of deposits

- Sampling and characterisation of ore tailings to be reprocessed to secure the supply of strategic metals on a European scale;

- Sampling and characterisation of batches of electrical and electronic waste for recycling.

Recycling of mining and industrial waste and exploiting the urban mine

- Development of processes for the physical separation of rare earth-bearing minerals in tailings;

- Co-processing of sulphur-containing ore tailings and post-consumer waste using microbial extractive metallurgy and control of associated environmental impacts;

- Recovery of strategic metals from electronic circuit boards and permanent magnets;

- Upcycling of concrete rubble.

Recycling of fine materials

- Flotation of fine particles to extract rare earths from ore tailings and luminophores;

- Treatment of powders from the manufacture of brake pads for the recovery of non-ferrous metals;

- Treatment of dredged sediments.

Treatment of industrial and mining effluents

- Recovery of metals and minerals in industrial wastewater.

BRGM's Plat'Inn platform for raw materials and the circular economy

Thirty ongoing projects

Plat’Inn offers different multi-scale mineralurgy/metallurgy equipment allowing both dry and wet treatments (crushing/ grinding, shredding, sampling, physico-chemical screening, thermal treatments, hydrometallurgical processes). The platform is also designed to strengthen BRGM excellence in fields such as biolixiviation (metals extraction by biological methods), electro-fragmentation and microwave technology (embrittlement and selective separation) and flotation (concentration). It also provides tools for process modelling and environmental assessments (LCA: life cycle analyses).

Some thirty projects are currently running in what is best described as an industrial-scale laboratory. They are the outcome of the BRGM's own research and experimentation programmes, its participation in French (ANR) and European H2020) collaborative RDI programmes and its numerous industrial partnerships. These projects focus more specifically on recycling and reusing mining and industrial waste, demolition waste and waste electrical and electronic equipment (WEEE) and other end-of-life products.

Available resources

Technical resources

More than 200 pieces of equipment catering for the following needs:

- Sampling and preparation of materials by crushing, grinding, micronisation, shredding and quartering;

- Separation technologies using gravimetric, magnetic, electrostatic, flotation, filtration and coagulation processes;

- Hydro- and biohydrometallurgy;

- Thermal treatment.

Flagship equipment for material embrittlement on a pilot scale:

- Selfrag (electrofragmentation);

- Micro-wave oven.

Digital tools

- Echant, Bilco, Usimpac for the simulation of processes;

- Thermoddem database on thermodynamics / kinetics of natural and industrial processes;

- Simapro and Ecoinvent database for life cycle analysis / environmental assessment.

Human resources

25 engineers, scientists and technicians specialising in sampling, process engineering, chemical engineering, biotechnologies, numerical modelling/simulation and environmental assessment.